Mail Us: [email protected] [email protected]

Call For Us: +86 18003790744 +86 18003790601 +86 18003797770

A slewing bearing, also known as a slew ring, is a kind of huge-size rolling bearing that can make the best use of its design in favor of facilitating oscillatory movements. It is usually comprised of two rings, an inner ring and an outer one, both or one of which are equipped with gear teeth. What makes power transmission perfect among them is those holes used for fastening purposes on both rings. Thus configured, this type of bearings act singly or in combination under various loads capacities while capable to bear axially and radially at the same time tilting moments generated thereby.

Slewing bearings were invented over 40 years ago but they took some time to become popular worldwide as components widely applied in machines throughout many industries within mechanical engineering; nevertheless it was China where such products started being mass-produced following introduction into Rothe Erde company’s design and technological know-how from former West Germany during early eighties’ last century. This was a major breakthrough point leading towards higher efficiency levels achieved by machine elements used across different branches.

SKF brand – one among most famous manufacturers operating today – has developed its own lineups consisting various types suitable for particular tasks like turrets moorings systems or cranes employed at offshore oilfields extraction sites. Working out those solutions required special sealing arrangements together with considerable application experience so that these items could deliver good performance even under severe environmental conditions; moreover there were proposals made by SKF engineers themselves concerning fully-customized monitors integrated into advanced lubrication/sealing systems which would help prolonging service life alongside improving operational characteristics through optimization measures taken into account during design phase itself. Furthermore being present globally enabled them not only offer their clients all needed products but also provide necessary services wherever required thus contributing greatly towards reducing expenses related with downtime occurrence besides increasing overall work efficiency levels worldwide too.

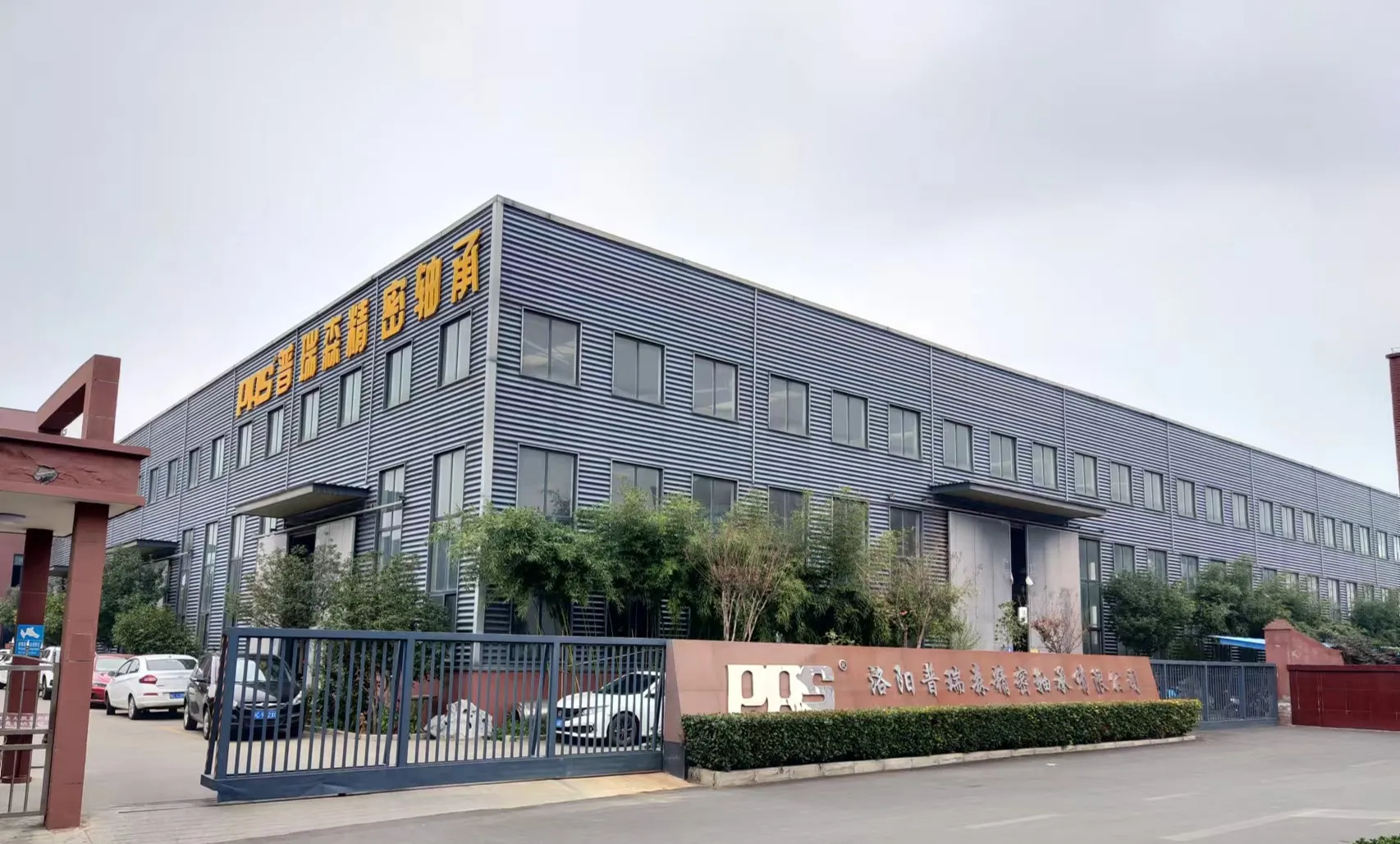

Luoyang Precision Precision Bearing Co., Ltd. is a high-tech enterprise which specializes in precision bearing production and research and development, our company covers 15,000 square meters. Since its establishment in 2003, our company has developed rapidly with 145 employees and 35 technicians of different types. Various professional equipment and testing instruments 135 sets, the total investment of fixed assets of more than 80 million yuan.

Our main products including cross cylindrical roller bearings, cross tapered roller bearings, thin section ball bearings, turntable bearings, high-precision slewing bearings, etc. The accuracy can reach P4, P2 level. We are committed to providing "professional, reliable and stable" products and services for global buyers.

PRS bearings are crafted from high-grade steel and top-quality polymers, ensuring exceptional durability and longevity. Our commitment to using superior materials means our bearings can withstand the harshest conditions, providing reliable performance for years to come.

Designed with energy efficiency in mind, PRS bearings reduce friction and heat generation, leading to lower energy consumption. This not only helps in reducing operational costs but also contributes to a more sustainable and environmentally friendly operation.

Every PRS bearing undergoes rigorous precision engineering processes, resulting in products that meet the highest industry standards. This meticulous attention to detail ensures a perfect fit and smooth operation, minimizing wear and tear and extending the service life of your machinery.

At PRS, we pride ourselves on providing outstanding customer service. Our team of experts is always ready to assist with product selection, technical support, and after-sales service, ensuring that you receive the best possible experience with our products.

A slewing bearing is a large-sized rotational support component designed to bear heavy loads and allow for rotation between two parts of a machine or structure. It typically consists of an inner ring and an outer ring, with rolling elements such as balls or rollers in between.

Slewing bearings work by transferring loads through rolling elements, which rotate within the inner and outer rings. This allows for smooth and efficient rotation while minimizing friction and wear.

There are several types of slewing bearings available, including ball slewing bearings, roller slewing bearings, and combined slewing bearings. Each type is designed for specific applications based on load capacity, speed, and environmental conditions.