Mail Us: [email protected] [email protected]

Call For Us: +86 18003790744 +86 18003790601 +86 18003797770

Roller bearings are a kind of bearing which uses cylinders to keep apart the moving parts of a machine. These types of bearings are made to decrease rotational friction and support both radial and axial loads. Roller bearings come in different shapes and sizes including cylindrical, spherical or tapered rollers each being suited for different applications depending on load type as well as direction. They serve as vital components in various mechanical systems that enable smooth rotation with least energy loss due to frictional forces while transferring power from one part to another.

The inner and outer rings of a roller bearing hold rollers and are made accurately so that they fit tightly together allowing them to carry heavy loads without failure. Usually, the rollers themselves are manufactured from hardened steel which can withstand continuous operation under high pressure and stress conditions. In order not let roll over each other or create unnecessary heat through rubbing against each other; cages or separators may be used which space them out evenly throughout their length thereby reducing friction between adjacent rolling elements along with wear caused by such contact points becoming hot spots This design enables these devices run at higher speeds than any other type of bearing could sustain considering its size thus making them suitable for use where heavy loads need be transmitted at relatively faster rates such as industrial machines automotive transmissions aerospace equipments among others.

When it comes down to servicing requirements; regular checking plus greasing should be done on roller bearings if they have to last longer while performing better too. As time goes by there might arise some wearing out situation within these devices leading into loudness increase followed by vibrations until they fail completely due lack care taken towards them during this stage . So timely replacement must always take place whenever worn-out bearing parts are identified since failure doings so can cause more harm than good especially when dealing with supporting structures like shafts or housings where damages caused by broken fragments may spread rapidly affecting even those sections not directly involved with failed component itself The latest technological advances incorporated into manufacturing procedures adopted when producing modern-day versions of these components have made them stronger than before hence capable enduring much higher stresses under extreme working conditions thus boosting operational efficiencies throughout different sectors within industry setting

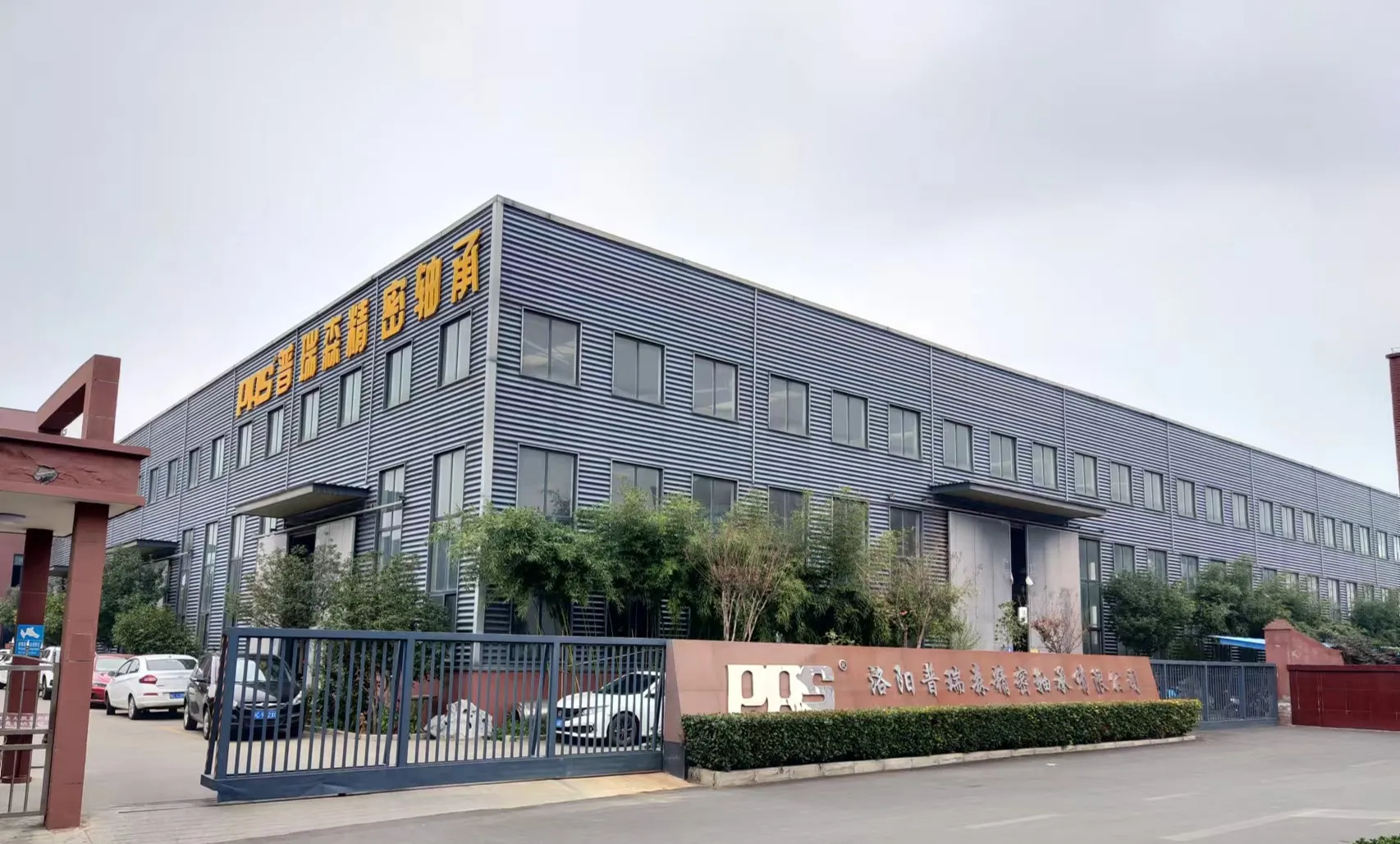

Luoyang Precision Precision Bearing Co., Ltd. is a high-tech enterprise which specializes in precision bearing production and research and development, our company covers 15,000 square meters. Since its establishment in 2003, our company has developed rapidly with 145 employees and 35 technicians of different types. Various professional equipment and testing instruments 135 sets, the total investment of fixed assets of more than 80 million yuan.

Our main products including cross cylindrical roller bearings, cross tapered roller bearings, thin section ball bearings, turntable bearings, high-precision slewing bearings, etc. The accuracy can reach P4, P2 level. We are committed to providing "professional, reliable and stable" products and services for global buyers.

PRS bearings are crafted from high-grade steel and top-quality polymers, ensuring exceptional durability and longevity. Our commitment to using superior materials means our bearings can withstand the harshest conditions, providing reliable performance for years to come.

Designed with energy efficiency in mind, PRS bearings reduce friction and heat generation, leading to lower energy consumption. This not only helps in reducing operational costs but also contributes to a more sustainable and environmentally friendly operation.

Every PRS bearing undergoes rigorous precision engineering processes, resulting in products that meet the highest industry standards. This meticulous attention to detail ensures a perfect fit and smooth operation, minimizing wear and tear and extending the service life of your machinery.

At PRS, we pride ourselves on providing outstanding customer service. Our team of experts is always ready to assist with product selection, technical support, and after-sales service, ensuring that you receive the best possible experience with our products.

PRS offers a variety of roller bearings, including cylindrical roller bearings, tapered roller bearings, spherical roller bearings.

Yes, PRS can provide roller bearings in custom sizes to meet specific application requirements.

PRS roller bearings are typically made from high-quality steel, with some models featuring additional materials such as brass, nylon, or stainless steel.