Mail Us: [email protected] [email protected]

Call For Us: +86 18003790744 +86 18003790601 +86 18003797770

PRSの薄型セクションベアリングは、最小限のスペースと軽量を必要とするアプリケーションのために綿密に設計されており、すべてのミリメートルが重要な環境で高いパフォーマンスと精度を提供します。これにより、コンパクトさと効率が最も重要な業界にとって理想的な選択肢となります。

PRSは、摩擦を最小限に抑え、回転の精度を最大限に高めるために作られたさまざまなタイプのベアリングを提供しています。私たちのベアリングは薄い壁と小さなサイズで構成されており、限られたスペースでも最適に機能します。ロボットや医療機器、その他の技術機器に必要な場合でも、これらの薄型ベアリングは重要な作業に必要な優れた性能、信頼性、効率を提供します。

PRSの薄型ベアリングはエネルギーを節約するように作られており、その結果、消費される電力の量を減らし、コストを削減します。私たちのベアリングに使用される材料は軽量で、摩擦を減らすように設計されているため、機械はより効率的に動作しながら、より低い温度で運転できます。環境に優しい方法で運営するのに役立つ薄型ベアリングを探しているときは、PRSを選択してください。

PRSによる密封薄型ベアリングは、長持ちし、メンテナンスが少なくて済みます。汚染に対する保護は、頑丈なシールによって提供され、潤滑剤の寿命も延ばすため、ダウンタイムやサービスにかかるコストを削減します。自動車産業セクターであれ、宇宙旅行であれ、清潔さが最も重要な場合には、これらの信頼できるコンポーネントがすべての期待に応えます!

PRSは,あなたの特定のアプリケーションのために作られた 細い切断軸承をあなたに提供します. 作業中に協力して 必要なものを特定します 穴の大きさ 外径 離空など 潤滑のオプションなどです PRSは常に精密な設計を 保証しています 製品が最高性能と耐久性を 維持するためにです

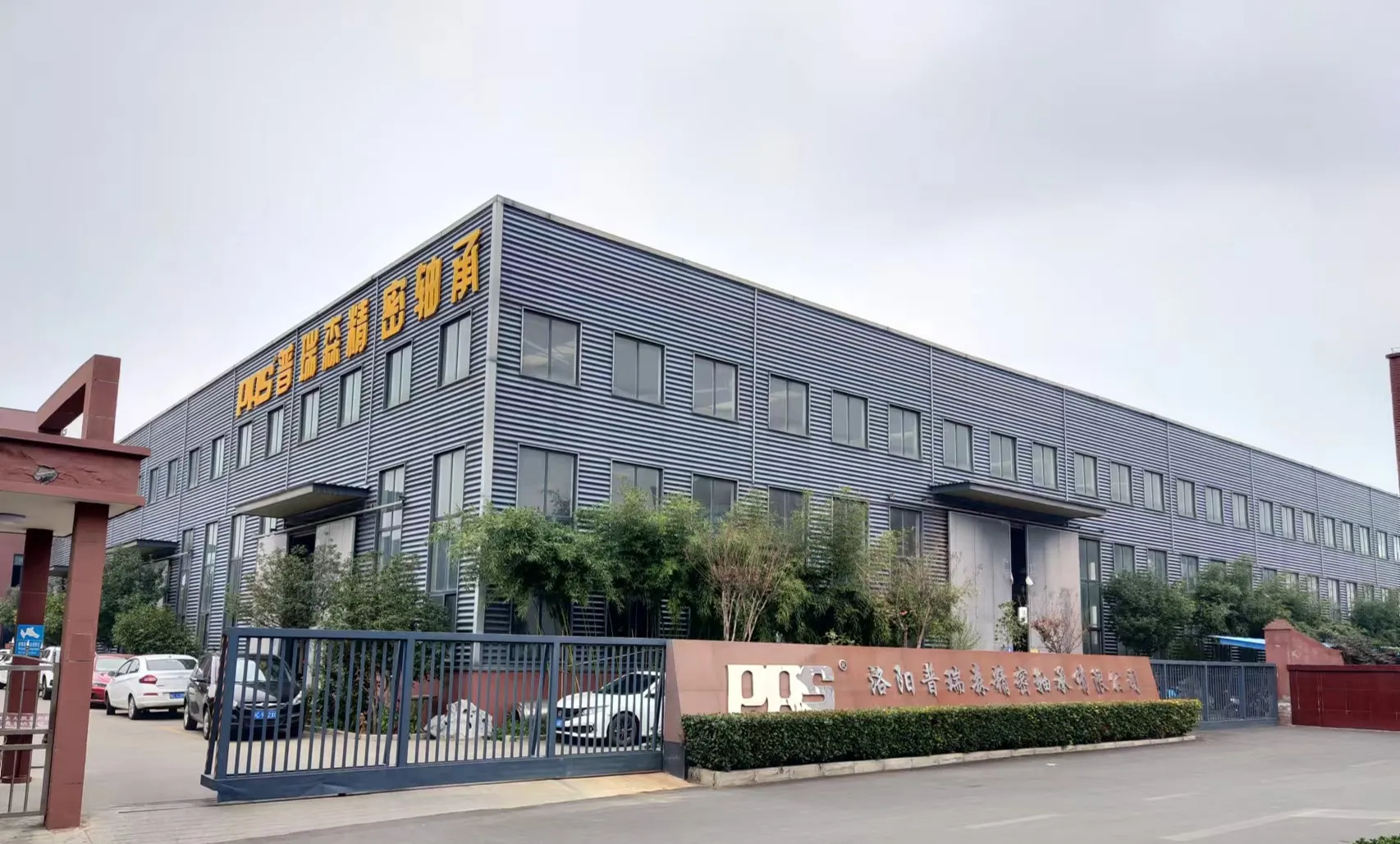

ローヤング精密精密ベアリング株式会社は,ハイテク企業です. 精密軸承の生産と研究開発に特化した 広さは1万5千平方メートルです 開始したからです 2003年に設立 社内では145人の従業員と35人の技術者がいます 専門機器と試験機器の 135セット,固定資産の総投資 総額は8000万元以上です

横円筒型ローラーベアリング,横角型ローラーベアリング,薄型ボールベアリング,ターンテーブルベアリング,高精度スウィリングベアリングなど,当社の主な製品です. 正確性はP4,P2レベルに達することができます. 提供することにコミットしています "プロフェッショナルで 信頼性があり 安定しています" グローバル購入者向け製品とサービス

PRSベアリングは高級鋼と高品質のポリマーで作られ, 卓越した耐久性と長寿性を保証します. 優れた材料を使用することに コミットしているため ローヤーは厳しい条件にも 耐えることができ 今後も 信頼性の高い性能を 提供できます

効率を考慮して設計されたPRSベアリングは摩擦と熱発生を軽減し,エネルギー消費を削減します 運用コストを削減するだけでなく より持続可能な環境に優しい運営にも貢献します

PRSベアリングは厳格な精密工学プロセスを経て 業界最高水準の製品が作られます 細部 に 細心の注意 を 払っ て いる こと に よっ て,機械 が 完璧 に 合っ て おり,スムーズ に 動作 する こと が でき,磨き が 少なく,使用 寿命 が 長く なります.

PRSでは 卓越した顧客サービスを提供することに誇りを持っています 専門家のチームは 製品選択,技術サポート,販売後のサービスで 常にサポートに備えていて,お客様が 製品で最高の体験を 確実に受けられるようにしています.

薄型ベアリングは、スペースが限られたアプリケーション向けに設計されたローリングエレメントベアリングの一種です。標準ベアリングと比較してセクションの高さが減少しており、ベアリングと周囲のコンポーネントとの間により大きなクリアランスを可能にします。

薄型ベアリングは、標準ベアリングよりも全体の高さが小さいため、狭いスペースや重量削減が優先される場所での使用に理想的です。通常、設計により体積あたりの荷重容量が高くなっています。

薄型ベアリングは、リングとローラーに高品質の鋼で作られており、真鍮、フェノール樹脂、またはポリアミドなどのさまざまなケージ材料が利用可能です。