Mail Us: [email protected] [email protected]

Call For Us: +86 18003790744 +86 18003790601 +86 18003797770

Equal-Section Thin-Walled Sealed Four-Point Contact Ball Bearing is a precision-engineered bearing that combines an equal-section design with a thin-walled, sealed construction to offer exceptional load-bearing capacity, space optimization, and protection against contaminants. Ideal for demanding applications where high radial and axial loads, compact design, and reliable performance are essential.

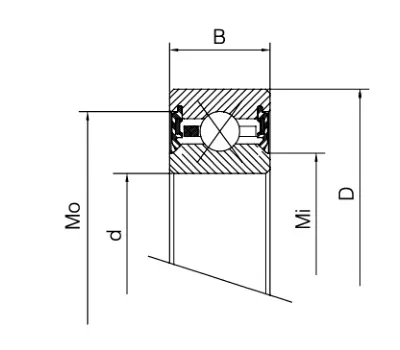

Equal-Section Thin-Walled Four-Point Contact Ball Bearing Model Size Table:

Product Description:

The Equal-Section Thin-Walled Sealed Four-Point Contact Ball Bearing is a premium-quality bearing designed for exceptional performance in demanding applications. Its unique combination of an equal-section design, thin-walled construction, and sealing technology ensures optimal load-bearing capacity, space optimization, and protection against contaminants. This bearing is precision-engineered to provide reliable and long-lasting performance in various industries and mechanical systems.

Key Features:

Applications:

The Equal-Section Thin-Walled Sealed Four-Point Contact Ball Bearing is ideal for a wide range of industrial and mechanical applications. It is commonly used in high-speed machinery, precision equipment, and automotive systems. This bearing is particularly suited for applications where high radial and axial loads are encountered, space optimization is essential, and protection against contaminants is required. Whether in manufacturing facilities, automotive assemblies, or any other demanding environment, this bearing delivers reliable performance and extended service life.

|

Major dimensions |

|

Rated loading |

|

|

||||||

d |

D |

B |

Radial |

Thrust |

|||||||

| Quiet | Move | Quiet | Move | KAYDON |

SILVERTHIN |

||||||

m |

Kg |

Co(N) |

Cr(N |

Co(N) |

Cr(N) |

(RPM) |

|||||

PX040UU |

101.600 |

120.650 |

12.700 |

0.249 |

9,340 |

6,300 |

23,400 |

12,500 |

2,280 |

JU040XP0 |

JSU040XP0 |

PX042UU |

107.950 |

127.000 |

12.700 |

0.263 |

9,880 |

6,510 |

24,730 |

12.770 |

2,160 |

JU042XP0 |

JSU042XP0 |

PX045UU |

114.300 |

133.350 |

12.700 |

0.277 |

10,410 |

6,720 |

26.070 |

12,990 |

2,050 |

JU045XF0 |

JSU045XP0 |

PX047UU |

120.650 |

139.700 |

12.700 |

0.295 |

10,940 |

6,920 |

27.400 |

13.210 |

1,950 |

JU047XP0 |

JSU047XP0 |

PX050LU |

127.000 |

14,605 |

12.700 |

0.308 |

11,520 |

7,120 |

28,740 |

13,520 |

1.860 |

JU050XP0 |

JSU050XP0 |

PX055UU |

139.700 |

158.750 |

12.700 |

0.336 |

12.590 |

7,500 |

31,400 |

13,880 |

1.700 |

JU055XF0 |

JSU055XP0 |

PX060UU |

152.400 |

171.450 |

12.700 |

0.367 |

13,660 |

7.870 |

34.070 |

14.320 |

1.570 |

JU060XP0 |

JSU060XP0 |

PX065LU |

165.100 |

184.150 |

12.700 |

0.395 |

14,720 |

8,230 |

36,790 |

14,680 |

1,460 |

JU065XP0 |

JSU065XP0 |

PX070UU |

177.800 |

196.850 |

12.700 |

0.422 |

15.790 |

8,590 |

39.460 |

15.210 |

1.360 |

JU070XP0 |

JSU070XP0 |

PX075LU |

190.500 |

209.550 |

12.700 |

0.449 |

16.860 |

8,930 |

42,120 |

15,480 |

1.270 |

JU075XP0 |

JSU075XP0 |

PXO80LU |

203.200 |

222.250 |

12.700 |

0.481 |

17.930 |

9,260 |

44.790 |

15,840 |

1,190 |

JU080XP0 |

JSU080XP0 |

PX090UU |

228.600 |

247.650 |

12.700 |

0.535 |

20.060 |

9,900 |

50.130 |

16.410 |

1.070 |

JU090XP0 |

JSU090XP0 |

PX100UU |

254.000 |

273.050 |

12.700 |

0.594 |

22,200 |

10,520 |

55.470 |

17.480 |

970 |

JU100NF0 |

JSU100XF0 |

PX110UU |

279.400 |

298.450 |

12.700 |

0.649 |

24,330 |

11,100 |

60,850 |

18,590 |

880 |

JU110XP0 |

JSU110XP0 |

PX120UU |

304.800 |

323.850 |

12.700 |

0.708 |

26,470 |

11.660 |

66,190 |

19.660 |

810 |

JU120XP0 |

JSU120XP0 |

Notes: