Mail Us: [email protected] [email protected]

Call For Us: +86 18003790744 +86 18003790601 +86 18003797770

Equal-section Thin-walled Sealed Deep Groove Ball Bearings, also known as Radial Contact Ball Bearings, are precision components designed for applications requiring high radial load capacity and space optimization. Their unique equal-section and thin-walled design offers excellent strength and durability while minimizing weight and material usage, making them an ideal choice for demanding mechanical systems where space is limited. These bearings are sealed to protect against contamination, ensuring reliable performance and extended service life.

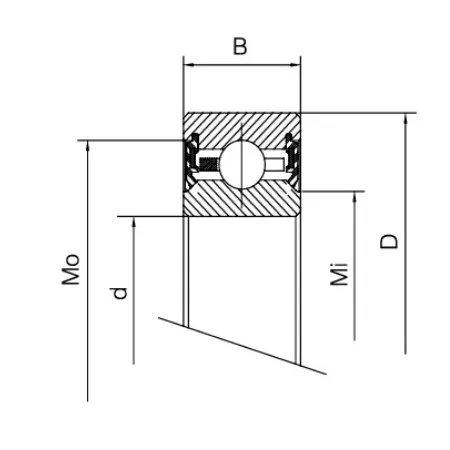

Equal-section Thin-walled Sealed Deep Groove Ball Bearings (Radial Contact Ball Bearings) Structure Diagram and Model Size Table:

Product Description:

The Equal-section Thin-walled Sealed Deep Groove Ball Bearings, also referred to as Radial Contact Ball Bearings, are precision-engineered components designed to meet the demands of high radial loads and space constraints in various mechanical systems. These bearings combine an equal-section design with a thin-walled structure, offering exceptional strength and durability while optimizing weight and material usage. The sealing feature protects the bearings from external contaminants, ensuring reliable and long-lasting performance.

Key Features:

Applications:

The Equal-section Thin-walled Sealed Deep Groove Ball Bearings are suitable for a wide range of applications where high radial loads, space limitations, and reliable performance are essential. They are commonly used in industries such as automotive, aerospace, robotics, and precision machinery. These bearings are ideal for high-speed operations, heavy-duty equipment, and any environment where protection against external contaminants is crucial for maintaining system integrity and longevity.

|

Major dimensions |

|

Rated |

|

|

||||

d |

D |

B |

Radial |

||||||

| Quiet | Move | KAYDON |

SILVERTHIN |

||||||

mm |

Kg |

Co(N) |

Cr(N) |

(RPM) |

|||||

PR040UU |

101.600 |

120.650 |

12.700 |

0.249 |

9,340 |

5,740 |

3,660 |

JU040CP0 |

JSU040CP0 |

PR042UU |

107.950 |

127.000 |

12.700 |

0.263 |

9,880 |

5,870 |

3,460 |

JU042CP0 |

JSU042CP0 |

PR045UU |

114.300 |

133.350 |

12.700 |

0.277 |

10,410 |

6,010 |

3,280 |

JU045CP0 |

JSU045CP0 |

PR047UU |

120.650 |

139.700 |

12.700 |

0.295 |

10,940 |

6,090 |

3,120 |

JU047CP0 |

JSU047CP0 |

PR050UU |

127.000 |

146.050 |

12.700 |

0.308 |

11,520 |

6,180 |

2,980 |

JU050CP0 |

JSU₀50CP0 |

PR055UU |

139.700 |

158.750 |

12.700 |

0.336 |

12,590 |

6,410 |

2,720 |

JU055CP0 |

JSU055CP0 |

PR060UU |

152.400 |

171.450 |

12.700 |

0.367 |

13,660 |

6,630 |

2,510 |

JTU060CP0 |

ISU060CP0 |

PR065UU |

165.100 |

184.150 |

12.700 |

0.395 |

14,720 |

6,810 |

2,330 |

JU065CP0 |

JSU065CP0 |

PR070UU |

177.800 |

196.850 |

12.700 |

0.422 |

15,790 |

6,980 |

2,170 |

IU070CP0 |

ISU070CP0 |

PR075UU |

190.500 |

209.550 |

12.700 |

0.449 |

16,860 |

7.120 |

2,030 |

JU075CP0 |

JSU075CP0 |

PR080UU |

203.200 |

222.250 |

12.700 |

0.481 |

17,930 |

7,340 |

1,910 |

IU080CP0 |

ISU080CP0 |

PR090UU |

228.600 |

247.650 |

12.700 |

0.535 |

20,060 |

7.700 |

1,700 |

JU090CP0 |

JSU090CP0 |

PR100UU |

254.000 |

273.050 |

12.700 |

0.594 |

22,200 |

7,920 |

1,540 |

JU100CP0 |

JSU100CP0 |

PR110UU |

279.400 |

298.450 |

12.700 |

0.649 |

24,330 |

8,360 |

1,410 |

JU110CP0 |

JSU110CP0 |

PR120UU |

304.800 |

323.850 |

12.700 |

0.708 |

26,470 |

8,780 |

1,300 |

JU120CP0 |

JSU120CP0 |

Notes: